Igloo JMRGGP Series Pastry Display Cases

Igloo JMRGGP Series Pastry Display Cases User Manual.

PROPERTIES OF THE UNIT

Purpose

“IMRTGGP and JMRWGGP” Dual service refrigerated open display merchandisers are universal cooling devices aimed to display deli, bakery, coffee shop, and market merchandise. Its glass-enclosed top is perfect for holding desserts, bagels, and bread, while its lower self-service bin is ideal for grab-and-go items like beverages in temperatures between +19C and +4°C with an ambient temperature between +15°C and +25°C and relative air humidity up to 60%, depending on the environment of the unit location.

Description of the unit

“JMRTGGP” and “JMRWGGP” display cases have dynamic cooling and independent temperature control for the top and bottom. The units are equipped with automatic condensate evaporation and automatic defrosting. The display parts of the unit are glass shelves on the inner frame and bottom shelves made of stainless steel. Our equipment is manufactured by modern technologies and has all certificates required by law. The description in this box signifies important information for user security and the proper operation of the device.

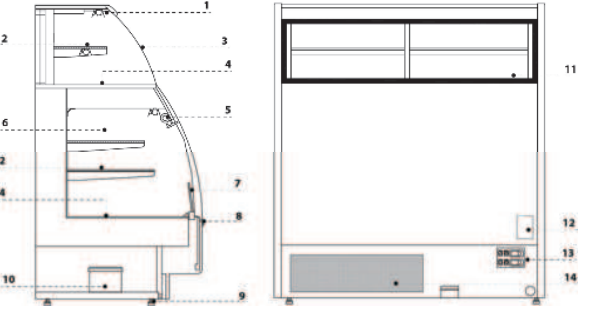

Overview

- LED lamp

- Display glass shelf

- Openable front glass on top display unit

- The bottom stainless steel display shelf is Curved,

- Night curtain

- Mirror finished side

- Front low glass

- Night curtain hook

- Leveling legs

- Compressor

- Sliding door

- Serial plate

- Control panel (thermostat, switches)

- Condenser cover (DO NOT BLOCK air louver!!!)

Technical data

PREPARING THE DEVICE FOR START-UP

The unit must be properly installed and located according to the installation instructions before it is used

Installation requirements

- Always use a dedicated circuit with the amperage stated on the unit.

- Plug into an outlet designed for the plug

- Do not overload the circuit.

- Do not use extension cords.

- Never use adapters.

- Never plug in more than one unit per electric circuit.

- If in doubt, call an electrician.

IGLOO will not warranty any equipment that is connected to an extension cord or an adapter plug. The equipment may be turned on after confirmation of the fire protection efficiency with the results of measures performed according to binding regulations!

Unit Location

- Install the unit on a strong and leveled surface.

- To ensure proper operation the unit must be leveled from front to back and left to right.

- The unit may malfunction if improperly leveled.

- Be sure there is sufficient ventilation around the entire unit.

- Select a location away from heat and moisture-generating equipment.

- Avoid installation in a high ambient or humid location.

- High ambient temperatures will cause the compressor to overwork.

- Humidity may cause rust, and condensation around glass or stainless steel and decrease the efficiency of the unit.

Connection and start-up

- Remove cardboard angles and protective foil.

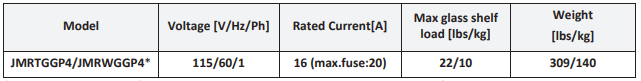

- Place the unit on an even and hard base. Then level the unit with the leveling legs.

A – Screw the leg in nuts

After installation of the equipment at the destination location it should be left to rest for at least 2 hours before turning it on (for devices with builtͲin compressors) to set the level of refrigerant to prevent problems with the start-up.

WARNING: Keep the cooling circuit from damage

- Turn on the main switch.

- The temperature on the thermostat control panel is PREͲSET.

- Turn on the light switch.

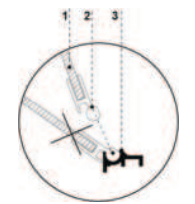

Hook height regulation

- Hook

- Protective pipe covering lamp cord

- PVC profile hiding the vertical frame post

Condensate container

Condensate container (empty the condensate!!!)

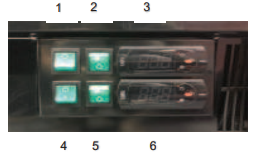

Control panel

- The main switch (turns on/off the unit) for the top unit

- The light switch for the top unit

- Thermostat for the top unit (temperature regulator) panel (Service details in Chapter 4)

- The main switch (turns on/off the unit) for the bottom unit

- The light switch for the bottom unit

- Thermostat for the bottom unit (Temperature regulator) panel (Service details in Chapter 4)

UNIT START-UP

The Temperature of the cooled space and aggregate operating cycle may fluctuate. This depends on numerous factors, such as the amount and temperature of products placed in the device and the temperature of the surroundings. The equipment should be placed in a dry and wellͲventilated area, ensuring proper air exchange (distance between the wall and the equipment– min. 10cm), out of sunlight, kept far from heat sources and devices enforcing air flow (ceiling and portable ventilators, blowͲin heaters). The equipment functions properly in a room, where the temperature falls within the appropriate climatic class. The operation of the equipment may worsen when operates outside the stated temperature range

Remarks and indications

- The display case has to be properly leveled, which will prevent noisy corking of the equipment and shall ensure proper water (condensate) outflow during defrosting

- After transporting the equipment, wait about 2 hours before starting up the unit.

- To ensure proper conditions for the stored products, do not load the shelves completely. Ensure an even load of shelves and not exceed the maximum load.

- The first filling of shelves should be performed after the unit has reached the desired cooling temperature. This principle should also be observed after a long pause in the operation.

- Do not block any ventilation holes, which would hamper the circulation of the cooled air. It is also necessary to ensure proper airflow around the equipment.

- Do not use electric devices inside the product-storing chamber.

- Avoid unnecessary opening of the doors and leaving them open for a longer period.

Temperature regulation

The thermostat is to obtain the set temperature within the equipment and maintain it within the determined temperature ranges. The manufacturer enters all settings of temperature regulators required for the normal functioning of the equipment. Before primary actuation, the user should control and possibly set the required temperature inside the equipment on the control panel. Digital display – displays the current temperature inside the equipment. It is forbidden to interfere with the systemic parameters of the thermostat, as this can lead to serious consequences, including damage to the cooling unit!

Carel thermostat control panel

- Diode 1ͲCompressor: This symbol is visible when the compressor is working. It blinks when compressor actuation is delayed by security procedures. It blinks in the following cycle: two blinks – pause when the constant working mode is activated.

- Diode 2ͲVentilator: This symbol is visible when evaporator ventilators are turned on. It blinks when the actuation of the ventilators is delayed by external disengagement or when another procedure is in progress.

- Diode 3ͲDefrosting: This symbol is visible when the defrosting function is activated. It blinks when the actuation is delayed by external disengagement or when another procedure is in progress.

- Diode 4ͲAlarm: This symbol is visible when the alarm is activated.

- Diode 5Ͳ Current temperature inside the equipment is displayed (decimal places displayed after the comma)

- Diode 6 – On/Off Switch: Pressing this button alone: for more than 3 sec. switch On/Off, Pressing with other buttons: pressed together with 8 activities/deactivates the continuous cycle.

- Diode 7 – Set/ Mute: Pressing this button alone: 1 sec. displays /sets the set point, more than 3 sec. accesses the parameter setting menu (enter password 22), mutes the audible alarm (buzzer), and starts up: hold the set/mute button for 1 sec. RESET current EY set / Pressed together (7 and 8) activate parameter reset procedure.

- Diode 8 – Defrost: Pressing this button alone: more than 3 sec. activates/deactivates the defrost. Pressing with other buttons: pressed together with 6 activates/deactivates the continuous cycle, Start Up: hold for 1 sec. displays firmware version

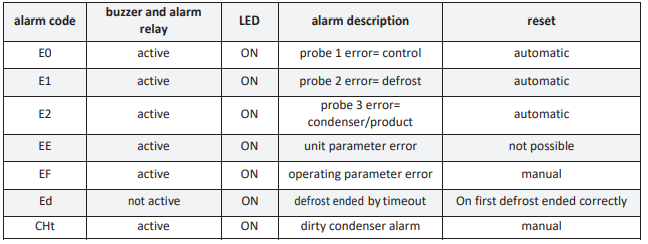

Table of alarms and signals

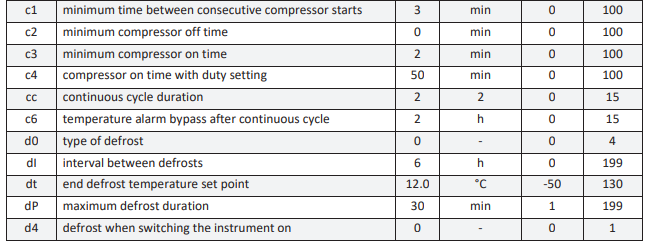

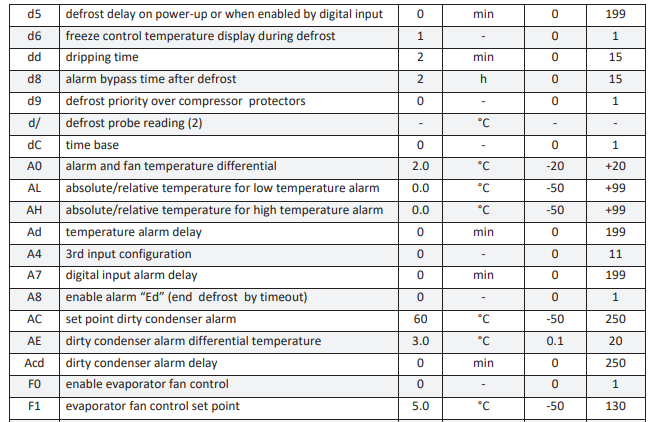

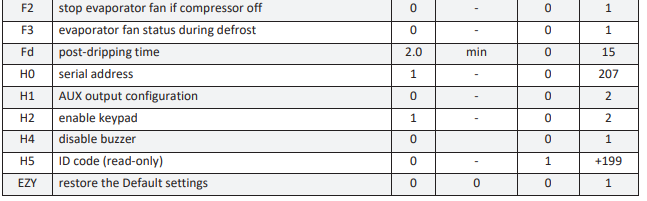

MODIFYING THE PARAMETERS

Parameter navigation

The operating parameters, modifiable using the keypad, are divided into two types: frequent (type F) and configuration (type C). Access to the latter is protected by a password (default= 22) to prevent accidental or unauthorized modifications.

Accessing the Type F parameters:

- Press the SET button for more than 3 s (if there are active alarms, mute the buzzers). The display shows the parameter code ‘PS’ (password);

- Use the UP and DOWN buttons to scroll the parameters. The LED corresponding to the category of parameters will be on;

- Press SET to display the value associated with the parameter

- Increase or decrease the value using the UP or DOWN buttons respectively;

- Press SET to temporarily save the new value and display the parameter again;

- Press the SET button for more than 3 s to permanently save the parameters and exit the parameter setting procedure

Table of easy compact parameters for model JMRTGGP

Cleaning and maintenance

- Protect electrical components against any damage or water spillage.

- Do not use a water stream to clean the equipment, only a moist cloth.

- Do not use any sharp objects to remove dirt!

- When cleaning inside the unit, do not leave the front glass panel open in the aluminum profile. Please remove the glass with the profile during cleaning.

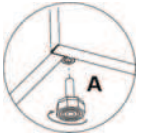

Disassembly of the front glass on top display unit

- Front glass

- Upper aluminum profile (lifted guide) of the glass

- Lower aluminum profile (hinge) of the glass

Cleaning the condenser

It is essential to keep the condenser of the device clean. Dirt may hinder the heat exchange, causing mainly an increase in electric energy consumption, and may cause damage to the compressor. To clean the condenser it is necessary to unscrew the sheet metal screws and pull the wind brace out of the catch by lifting it. Clean condenser lamellas with the help of a soft brush or paintbrush.

SERVICE

Faults identification and repair

In case of any difficulties during the actuation of the equipment or its operation, please return to this chapter in this manual, which will explain the performed operation. If you still experience difficulties, the following might help you solve the problem.

The equipment is not working… – Make sure that:

Voltage and frequency are compliant with those recommended by the manufacturer, 115V/60Hz.

Service

IGLOO Refrigeration service

- Telephone number: 416-663-3051 or (toll-free) 1-888-408-8819

- E-mail: service@iglo0400.com

If after checking the points described in Chapter 6.1 “Faults identification and repair” the unit still does not work properly, Please contact Technical Service @ IGLOO Refrigeration.

124 Norfinch Dr. Toronto, ON. M3N 1X1

- Tel: 416-663-3051

- Toll Free: 1-888-408-8819

- Fax: 416-663-5793

- www.igloorefrigeration.com