Panasonic TPF Series Conductive Capacitors

Panasonic TPF Series Conductive Capacitors User Manual.

Features

- Super low ESR (5 mΩ max.)

- Large capacitance (1000 μF max.)

- RoHS compliance, Halogen free

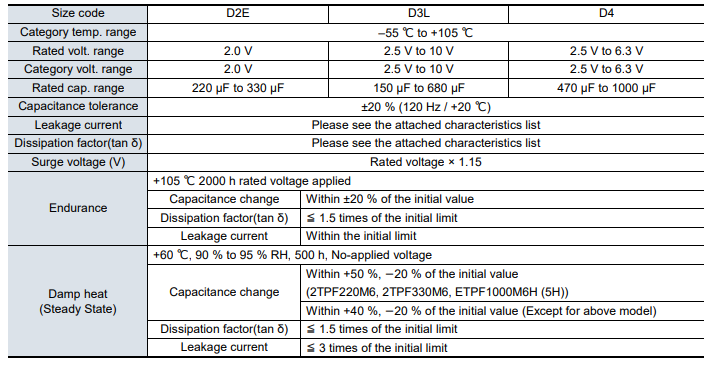

Specifications

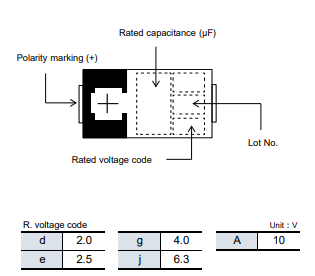

Marking

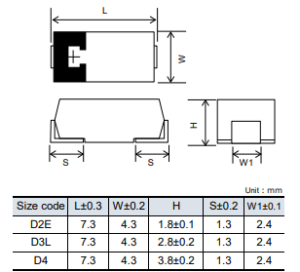

Dimensions (not to scale)

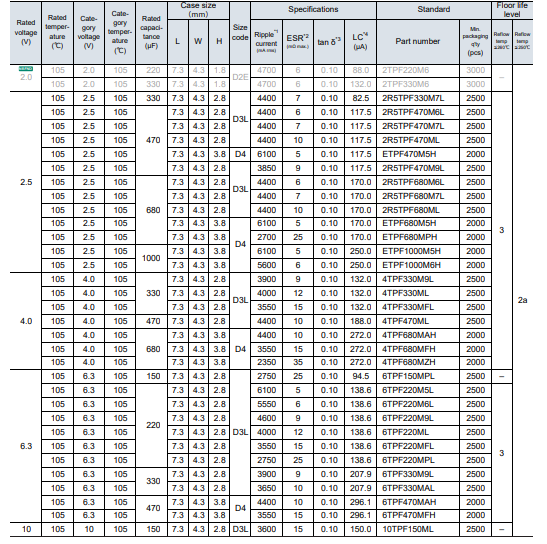

Characteristics list

- Ripple current (100 kHz / +45 ℃)

- ESR (100 kHz / +20 ℃)

- tan δ (120 Hz / +20 ℃)

- After 5 minutes

- Please refer to each page in this catalog for “Reflow conditions”, “Taping specifications” and “Floor life level”.

- A small order quantity (500 pcs/reel) is available with the TPF series. Please contact our sales representative if you prefer it.

Guidelines and precautions

Regarding the technical information and use of our products described in this online catalog.

- The quality and performance of our products as described in this online catalog only apply to our products when used in isolation.

- Please ensure safety using protection circuits, redundant circuits, etc.

- The technical information in this online catalog provides examples of our products’ typical operations and application circuits.

- If any of our products, product specifications, and/or technical information in this catalog is to be exported, the laws and regulations of the exporting country, especially about security and export control, shall be observed

<Regarding the Certificate of Compliance with the EU RoHS Directive/REACH Regulations

- The switchover date for compliance with the RoHS Directive/REACH Regulations varies depending on the part number or series of our products.

- When you use the inventory of our products for which it is unclear whether those products are compliant with the RoHS Directive/REACH Regulation, please select “Sales Inquiry” in the website inquiry form and contact us.

Notices

- Applicable laws and regulations This product complies with the RoHS Directive (Restriction of the use of certain hazardous substances in electrical and electronic equipment (DIRECTIVE 2011/65/EU and(EU)2015/863))

- Limited applications

This capacitor is designed to be used for electronic circuits such as audio/visual equipment, home appliances, computers and other office equipment, optical equipment, and measuring equipment. - Intellectual property rights and licenses

The technical information in this specification provides examples of our products’ typical operations and application circuits.

Items to be observed

For specification

- This specification guarantees the quality and performance of the product as individual components.

- Do not use the products beyond the specifications described in this document

Conditions of use

Before using the products, carefully check the effects on their quality and performance, and determine whether or not they can be used.

- In liquid, such as Water, Oil, Chemicals, or Organic solvent.

- In direct sunlight, outdoors, or in dust.

- In vapor, such as dew condensation water of resistive element, or water leakage, salty air, or air with a high concentration corrosive gas, such as Cl2, H2S, NH3, SO2, or NOx.

- In an environment where strong static electricity or electromagnetic waves exist.

- Mounting or placing heat-generating components or inflammables, such as vinyl-coated wires, near these products.

Please arrange circuit design for preventing impulse or transitional voltage. Ensure that the voltage is lower than the rated voltage in the following conditions. shock voltage circuits, transient phenomena in which excessive high voltage is applied in a short period, or when pulse high voltage is applied.

Application Guidelines (POSCAP

Circuit design

Prohibited circuits Since problems can be expected, POSCAP cannot be used on the following circuits.

- High-impedance voltage retention circuits

- Coupling circuit

- Time constant circuits

- Circuits are greatly affected by leakage current

- The circuit in which two or more POSCAPs are connected in a series to raise the endurance voltage.

Failure and life-span

The failure rate is 0.5 %* / 1000 h (Confidence level: 60 %) based on JIS C 5003. The main failure modes are as follows. * B2 size or less: 1.0 %

Contingency failure

The main causes of failure are thermal stresses caused by the soldering or thermal use environment, along with heat stresses, electrical stresses, or mechanical stresses.

- If POSCAP emits smoke, turn off the main power of the equipment. In this case, keep your face and hands away from the area.

- It may take a few seconds to a few minutes before POSCAP emits smoke by the situation. When using a protection circuit, design the product so that it operates during this period.

- If the smoke comes into your eyes, rinse immediately. If the smoke is inhaled, gargle immediately.

- In case a large current continues to flow after a short circuit, in the worst case, the shorted-out section may ignite.

Wear-out failure (lifetime)

When the lifetime exceeds the specified guaranteed time of Endurance and Damp heat, the electrolyte might insulate and cause electric characteristic changes. This is called an open circuit.

Reduction of failure stress

- POSCAP with reduced environment temperature, ripple current and applied voltage. Failure rate

- In the case of the endurance which is 105 °C 2000 h.

- 0.5 %/1000 h (Environment temp. : 105 °C, Rated voltage or Category voltage applied)

- In the case of the endurance which is 105 °C 1000 h or 125 °C 1000 h.

- 1.0 %/1000 h (Environment temp. : 105 °C, Rated voltage or Category voltage applied)

- In the case of the endurance which is 85 °C 1000 h.

- 1.0 %/1000 h (Environment temp. : 85 °C, Rated voltage applied)

- 1.4 Check the rated performance

Operating temperature and ripple current

- Set the operating temperature so that it falls within the range stipulated in this delivery specification.

- Do not apply current that exceeds the allowable ripple current. (For questions regarding the TQC series, please contact us.)

- The ESR values specified in the characteristics list are factory default values. ESR values may change (increase) beyond the specified values depending on the customer’s use conditions

Mounting

Protect circuit

The failure mode of POSCAP is the short mode. When it breaks down, a short electric current flows to it. POSCAP gives off heat by this short current. Do the following considerations in design fully for safety because it has a bad influence on the part around POSCAP due to this heat.

Considerations when soldering

The soldering conditions are to be within the range prescribed in this delivery specification. If the specifications are not followed, there is the possibility of degradation of electric characteristics and lifetime when soldering is conducted under conditions that are harsher than those stipulated.

Other POSCAP’s Electrical characteristics are affected by temperature and frequency fluctuations.

Design circuits after checking the amount of fluctuation.

Storage

- Please make storage of POSCAP sealing up in the reel and the moisture-proof bag at the time of delivery in the following environment. Also, set the storage period for unopened as 18 months or shorter after shipment from the factory.

- Room temperature and room humidity (generally: 15 to 35 °C, 45 to 75% RH ) are desirable.

- Please unseal the moisture-proof bag just before mounting and use up POSCAP in the moisture-proof bag.

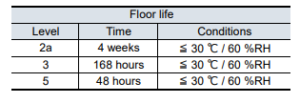

- Storage conditions after opening the moisture-proof bag are as follows.

Intellectual property right

We, Panasonic Group are providing the product and service that customers can use without anxiety, and are working positively on the protection of our products under intellectual property rights. Representative patents relating to POSCAP are as follows: